We offer great products to our clients.Our main products include:COF bonding machine for TV and phones,Laser repair machine for TV and phones,Polarizer repair machine and all kinds of accessories and spare parts.welcome to visit us to be our happy partners.

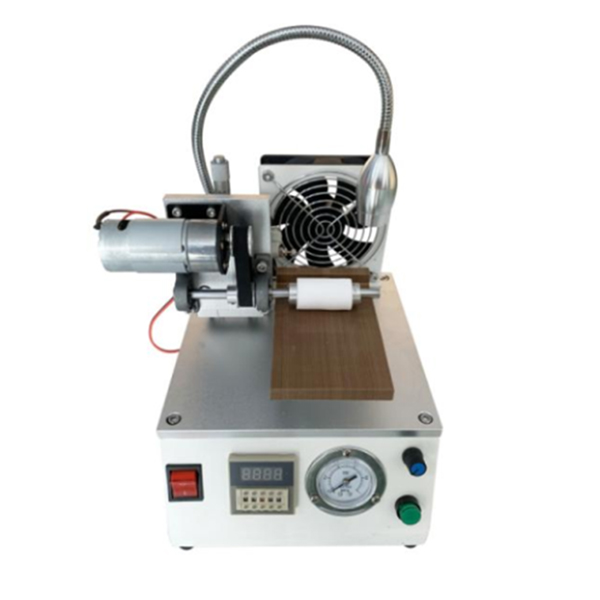

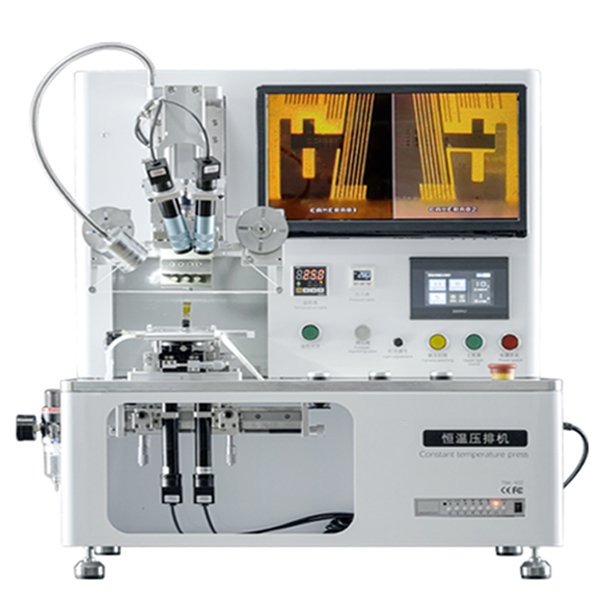

FOG bonding machine for phone repairing. it can bonding the FPC/COF on the glass,FPC,touch panels,and PCB.. remove the old and bad FPC from the phone, then use the bonding machine to bond the new FPC or COF on the glass, then it will work good.

Polarizer film repair machine,it has polarizer film remove machine and polarizer film laminating machine. we remove the bad file first,then laminating the good new polarizer film. then we solve the polarizer problem,and the TV look like new one.

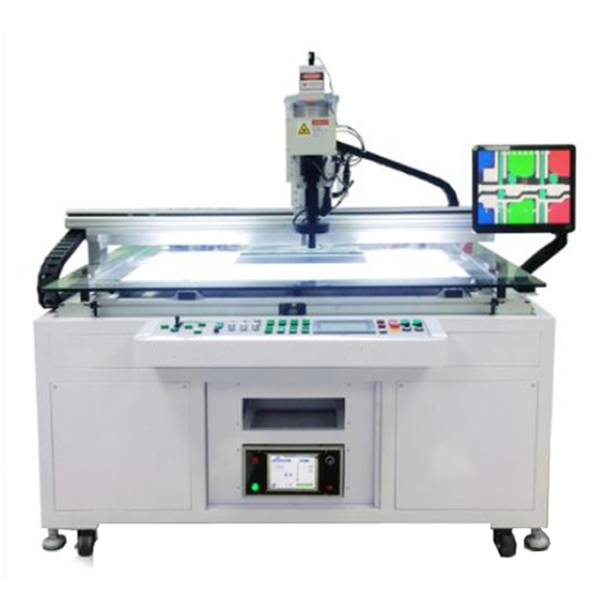

Use high-energy pulse laser to cut or fuse specific circuits in the ito conductive coating of OLED/LED/LCD, repairing the normal function of OLED/LED/LCD circuits.

The device is using laser (good monochromatic, good coherence, good direction) &(high brightness) characteristics, under various kinds of optics effect, focused into high-energy laser,use different wavelengths(1064nm,532nm) repairing Short Circuit Defects inTFT-LCD Processes,to improve the yield rate.

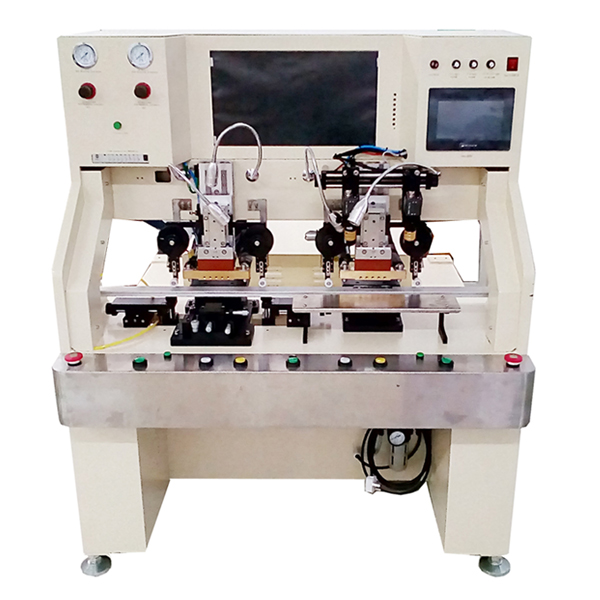

Double head COF bonding machine for TV repair, one head for COF glass side ,one head for COF on PCB side, they are different size and can set different temperature and pressure and time for different ACF tape size. it is better for bonding in good quality.

Singel head bonding machines for TV repair..it use the same bonding head to bonding the COF on glass side and COF on the PCB side.. to change the bad COF ic to new good ic,then repair the TV to good conditions.

Most popular of our products

We work with new customers and grow their businesses

We have mentioned that the principle of COF bonding machine is to bond ACF and explode another ACF conductive particle at a certain temperature, pressure and time to solidify ACF adhesive, so as to realize mechanical connection and electrical conduction between liquid crystal glass or PCB and flexible circuit board (FPC).The simple understanding is to […]